Knowledge

Learn from experts - your way

Find expert insights and trusted information designed to support both healthcare professionals and patients. Explore articles, videos, and resources that advance clinical knowledge and improve patient care.

Gain insights from experts

Find expert insights and trusted information aimed to support both healthcare professionals and patients. Explore articles, videos and resources that advance clinical knowledge and improve patient care.

View all articlesBuild your learning pathway

The best way keep learning is to follow a plan. Register on the Clinical Learning Hub to keep track.

Start learning todayHighlighted articles

-

Wound care | 5 min read Safetac®: the innovation that changed wound care forever

What is Safetac and how does it improve patient experience and outcomes? As any clinician knows, patients can endure terrible pain when a dressing sticks to the wound or damages the skin. Likewise, a dressing that doesn’t protect the wound edges can cause maceration which slows down healing and can prolong suffering for those with chronic wounds. We know that clinicians want to prevent this suffering and offer their patients more effective treatment options. That’s where Safetac comes in. Safetac is the original game-changing contact layer. It is used across Mölnlycke’s advanced adhesive dressing ranges and facilitated the development of the first bordered silicone foam dressing. Safetac’s innovative design allows the dressing to mould softly to the skin and yet not stick to the moist wound.1-5 It will protect the wound edges to minimise risk of maceration1, 4, 5, 7 and make the dressing easy to remove without damaging the skin.1-4 It all adds up to a less painful experience for patients at dressing change.1-6, 9 The combination of less pain and less skin and wound damage is the reason that numerous randomised controlled trials associate dressings with Safetac with faster wound healing.2, 3, 4, 9 Which dressings feature Safetac technology? Since its launch at Mölnlycke, Safetac has been a key technology behind our most successful dressings. The range of dressings with Safetac has expanded over the years and there is now a foam dressing with Safetac for almost every type of wound: The Mepilex range with soft conformable foam is suitable for many chronic wounds. The newest member of this family, Mepilex Up, is designed especially for patients struggling with VLUs or similar exudating wounds. Mepilex Border offered revolutionary exudate management and is now superseded by the next-generation, uniquely conformable Mepilex Border Flex, with its increased ability to stay in place. Silver-infused dressings such as Mepilex Ag deliver gentle and effective burn care with an antimicrobial effect. Mepilex Border Sacrum and Mepilex Border Heel have extended Safetac’s influence beyond healing and into the prevention of pressure ulcers. Other advanced dressings also feature Safetac: The Mepitel range, the first wound contact layers to incorporate Safetac, now includes Mepitel Film, a dressing uniquely proven to reduce radiotherapy-induced skin damage.8 Mepilex Border Post-Op, the advanced dressing for surgical incisions, was developed specifically to help reduce complications and support patients’ early mobilisation.1-6 How well-trusted is Safetac technology? Since its launch, Safetac has been used around the world to improve the wound care experience of hundreds of millions of patients. Safetac is trusted with good reason. At Mölnlycke, we are careful to support our products with robust evidence: more than 450 peer-reviewed findings confirm Safetac’s performance advantages. the evidence includes more than 30 randomised control studies. What could Safetac silicone dressings mean for your patients – and your budget? We know clinicians want to reduce patient suffering with less painful treatment options that support faster healing and improved outcomes. We also understand the pressures to reduce the cost of care. In addition to improving the patient experience at dressing change, Safetac also: protects new tissue and intact skin so wounds are undisturbed, supporting faster healing 1-9 seals wound margins to protect skin from leaks and maceration1, 4, 5, 7 By supporting faster healing, Safetac can not only improve the patient experience, it can also reduce the cost of treatment.2, 6, 9, 10 What is the story behind the development of Safetac technology? Safetac was invented by a young product designer at Mölnlycke called Tomas Fabo at a time when advanced wound care technology was in its infancy. Tomas had seen at first hand the pain patients can experience during dressing changes and became driven by the need to prevent this suffering. He began experimenting – even working at night in his own kitchen. Eventually he developed a type of silicone that was to become the key component of our early Mepitel range launched in 1989. Its promise was simple: it wouldn’t stick to the wound and it wouldn’t damage the skin and therefore, be less painful to remove. The rest is history. Tomas achieved his aims and Safetac continues to be at the heart of our advanced dressing ranges, including our most recent innovation, Mepilex® Up. How has Safetac changed the way we think about wound care? Since the launch of Mepitel® in 1989, Mölnlycke has sold well over 4 billion dressings with Safetac, helping millions of people experience less painful healing and preventing hundreds of thousands of pressure ulcers. Thanks to Safetac, wound care is now gentler, more effective, and more innovative than ever before.

-

Gloves | 2 min read The dangers of powder in surgical gloves

Surgical glove powder can cause the following adverse health effects: Increased risk of surgical site infections (SSIs) Glove powder can trigger reduced resistance to infection, bacterial environmental contamination, foreign body reaction, delayed wound healing, adhesion formation and granuloma formation 1 2. All of these potential consequences can increase the risk of surgical site infection (SSI) 3. Latex allergy and occupational asthma Powdered latex gloves have been implicated as the largest single contributor to the latex aeroallergen levels in a healthcare facility 4 5. Latex proteins can be aerosolized by attaching to glove powder. This not only increases the risk of acquiring a latex allergy, but can also increase the risk of acquiring occupational asthma 6 . Glove powder increases latex allergy sensitization, potentially eliciting delayed hypersensitivity reactions. Powdered surgical gloves show higher levels of natural rubber latex allergens than gloves that are powder-free. This allows for the potential increase in latex sensitization and/or Type I reactions upon direct and indirect contact 7 8 9 10 11 Biogel surgical gloves: powder-free since 1984 Every single Biogel® surgical glove is powder-free, and has been for over 40 years. Biogel sold the world's first powder-free surgical glove in 1984, and over 40 years later, Biogel is still the only major surgical glove brand with an exclusively powder-free range.

-

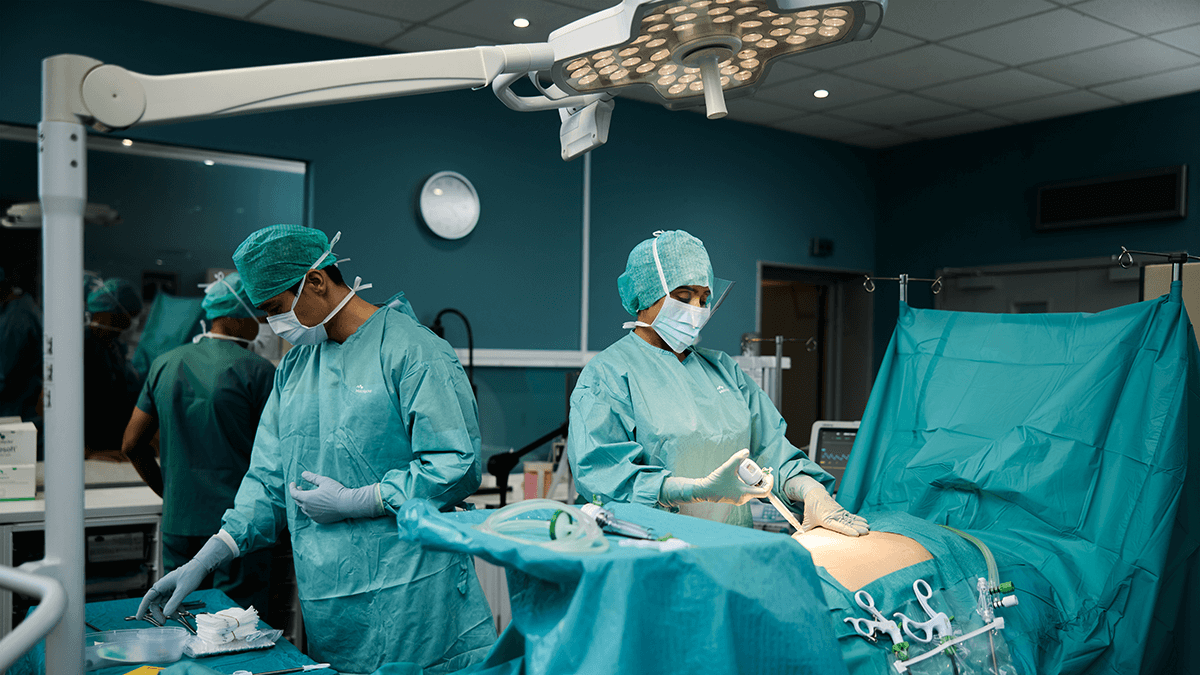

Surgical | 2 min read All-in-one speciality drapes offer many benefits

Speciality drapes for surgery not only offer the infection control measures required in an operating room with their single-use nature but also meet the specific needs of particular surgical interventions. And with consideration for OR efficiency, surgical drape packs can add greater efficiency and time savings. Speciality surgical drapes for OR safety and efficiency Mölnlycke offer a comprehensive range of speciality drapes. The operating room is home to all different types of drapes, including universal sets, but intervention-specific all-in-one drapes have relevant features integrated in the drape for easy and efficient draping. Integrated pouches and tube holders to create an organised working field. Speciality drapes designed specifically for a given procedure, such as a knee operation or orthopaedic operation, offer coverage and protection where it is most needed, thereby reducing the risk of contamination. With fewer parts to handle, fewer steps to take and a shorter, more efficient set-up time, the patient is draped and ready for the procedure to begin faster. This contributes to OR safety and efficiency by: Making setup faster and more efficient, cutting down on prep and overall time in OR Single-use or disposable surgical drapes support aseptic practice Enabling more procedure-specific patient safety and ease of use for OR personnel Speciality drapes are designed to be optimally folded – the folding allows for aseptic application, easy for one person to drape. Allow for easy and efficient draping by one person For saving time – 3 times faster than draping with a universal drape solution¹ Fewer parts, fewer steps – for reducing the risk of contamination²

-

Surgical | 4 min read One hospital achieves 37% more OR procedures using ProcedurePak®

As time management in healthcare, particularly in the surgical field, becomes more important, hospitals are actively looking for more efficiency from fewer resources. One hospital in France achieved significant improvements to operating room efficiency, according to a Mölnlycke ProcedurePak efficiency study. By implementing surgical procedure trays, European hospitals achieved 40-55% time savings in the operating room, making it possible to carry out more surgical procedures – around 37% more procedures in one hospital in France. [Video section] France Cathérine Laurent, OR nurse, Hôpital Privé des Peupliers, Groupe Générale de Santé, Paris, France Exploring how to improve operating room efficiency Hospitals in Europe are traditionally supplied with single-packed sterile products for surgical procedures. For each procedure, the nurses in the operating room need to source surgical instruments in the operating room and collect required materials from the storeroom unit by unit and set it all up for each procedure. Other necessary steps to get the right material in place include stock-taking and ordering, as well as warehousing and transportation. Hospital management today is striving for the most efficient treatment procedures without compromising on quality or safety. Thus there is increasing pressure to handle more interventions while relying on unchanged resources1, 2. Optimising internal processes to improve efficiency has become more and more important, and more effective operating room inventory management, down to the procedure level, has been identified as a way to achieve greater efficiency in the operating room. Study aim: Quantifying time savings from procedure trays The aim of the study was to investigate the effects of and quantify time savings when implementing ProcedurePak trays. Method This was an open prospective study performed as case studies in different hospitals located in Germany, France and Sweden. A total of 26 different ProcedurePak trays were used. For each of the hospitals the single-use material process was studied, from ordering of materials to disposal. This process typically consists of 6 main processes: internal order and delivery, receiving of goods in the surgical department, preparation and clean-up of surgery, external order, receiving of goods via the purchasing department and invoicing. The steps can be broken down into sub-processes and activities. For example, the main process – preparation and clean-up – can be broken down into 14 sub-processes or 33 activities. Each step in the process was described and measured both before and after implementation of the Mölnlycke ProcedurePak trays. For every step of the process, the time and cost drivers were identified by studying practical use and measuring time. Total annual time-saving after implementation of ProcedurePak trays in Germany. Results: Across hospitals, 40-59% time savings achieved The results of the study show that following the introduction of ProcedurePak trays, time-savings in the single-use material process were between 40% and 59% in the hospitals studied. The magnitude of the time-savings depends on several factors, including the number of different ProcedurePak trays used, number of components in each tray and the number of procedures performed with trays. The largest time savings were found in the preparation and clean-up of surgery, which is a key metric for operating room waste management initiatives. But time savings were also shown in other process steps. The time savings were used in different ways depending on individual objectives of the hospital, for example: Performance of additional surgical procedures, giving patients more timely treatment and maximising use of OR resources In the French hospital 37% more surgical procedures were performed following implementation. In the German hospital the number of interventions increased by 18% per year. Training of staff. Conclusions The case studies show that significant time-savings (40-59%) can be gained through implementing Mölnlycke customised procedure trays for surgical procedures in the operating room. The freed-up time makes it possible to perform additional surgical procedures. The financial effect of this is an area for further research. [Download] France case

FUN ANIMATED WAY TO LEARN

Wound Talks: 10 Essentials of Wound Healing

Are you able to hear what wounds are trying to tell you? Do you know how to tell when wounds are healing normally by what the wound itself “says”?

Join us to get healing moving.

Why learn with us

-

Learn from industry leaders

Access the expertise of top industry professionals with years of hands-on experience.

-

Advance your skills

Stay ahead with targeted learning that enhances your skills and enriches your career.

-

Earn recognised certificates

Showcase your achievements with certificates that highlight your dedication to healthcare excellence.